Inspection Procedure of Boilers

Inspection Procedure and Checklist of Boiler for Registration and Renewal under Boilers Act, 1923

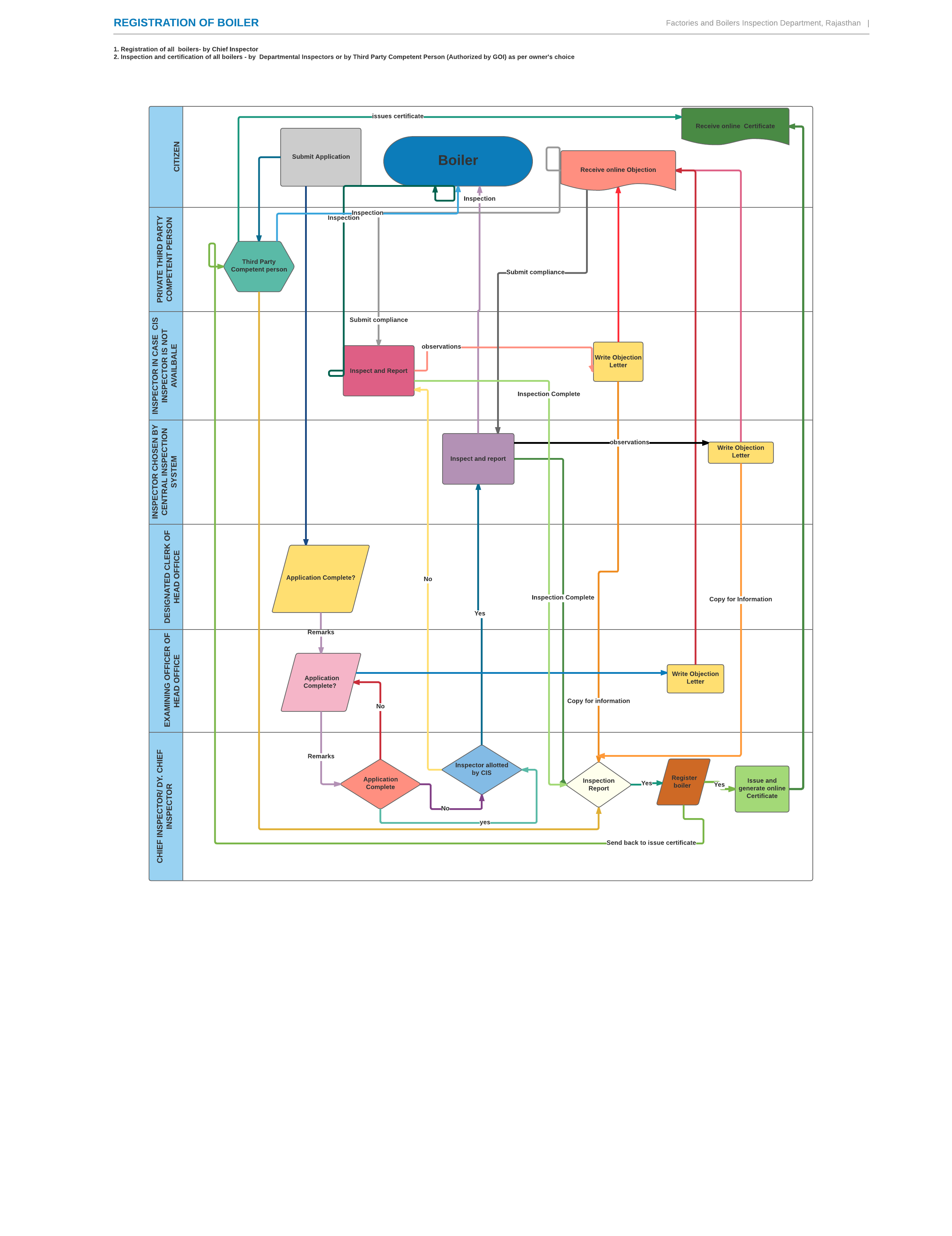

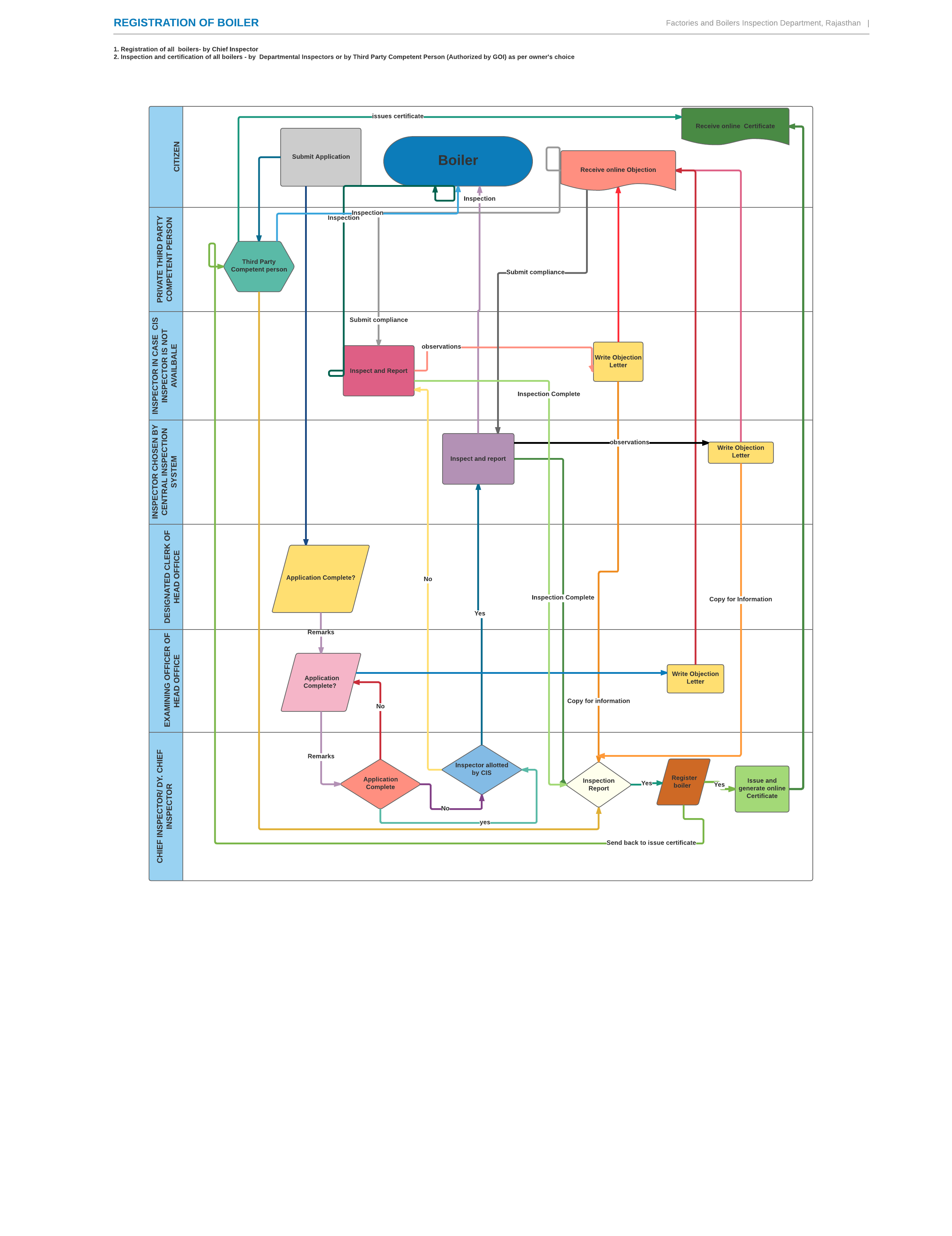

2. Process Flow Map for Boiler Inspection and Registration

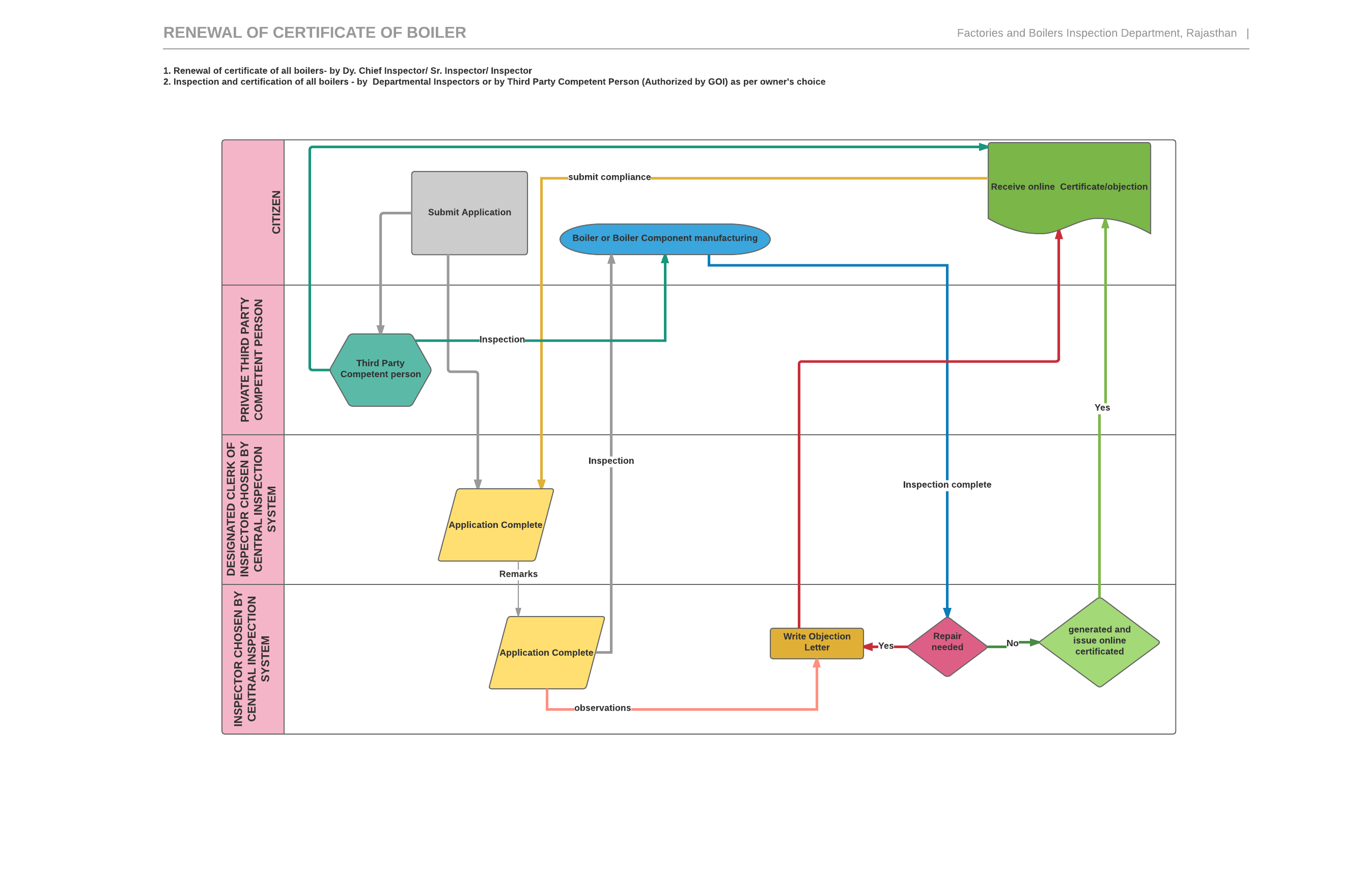

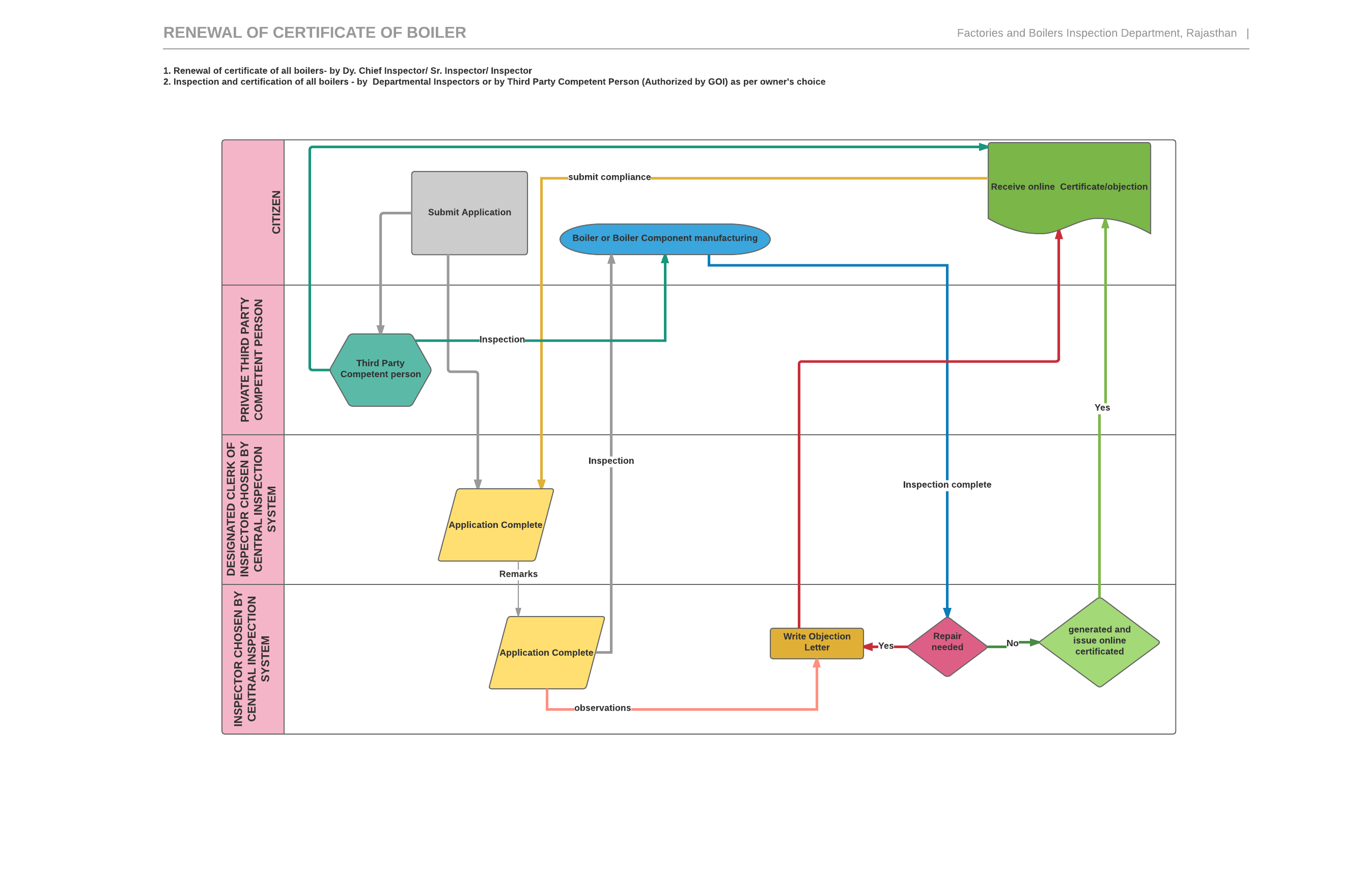

4. Process Flow Map for Boiler Inspection and Renewal

Inspection Procedure of Boiler for Registration under Boilers Act, 1923

| Steps | Procedure | Remarks |

|---|---|---|

|

Step 1 |

Boiler owner shall Submit application with relevant documents to the Inspector or competent person (Third Party) for registration of boiler. Visit www.rajfab.rajasthan.gov.in | You can see the audit trail for the actions in RajFAB web application. |

|

Step 2 |

Inspection of the boiler is allotted to an inspecting officer through Central Inspection System | Click here to know more |

| Step 3 | In case of packaged boiler (Case A)

|

Physical Inspection at site carries out by the Inspector/Competent person (Third Party). Documents to be kept ready for inspection-

|

| Step 4 | Boiler owner has to produce to the Inspector/Competent person (Third Party)all documents and test reports related to boiler, boiler components, mountings, fittings and steam pipeline before final hydraulic test. | |

| Step 5 | After inspection Inspector/Competent person shall prepare Boiler and steam pipe line inspection reports and submit inspection reports along with all documents and test reports to Chief Inspector of Factories & Boilers to register the boiler within 30 days. |

Inspection Procedure of Boiler for Renewal under Boilers Act, 1923

| Steps | Procedure | Remarks |

| Step 1 |

|

Boiler owner may choose any inspector or Competent Person (Third Party) in the State for inspection of his/her boiler during submission of application. |

| Step 2 |

|

Owner shall prepare the boiler for inspection. |

| Step 3 |

|

All welding work shall be carried out by a certified welder. |

CHECKLIST: INSPECTION FOR REGISTRATION OF BOILER

| GENERAL INFORMATION | |

|---|---|

| Date of Inspection | |

| Name of Owner/Factory/Premises | |

| Address of Factory/Premises | |

| Boiler Maker No. | |

| Name of Boiler Manufacture | |

| Year of Manufacture | |

| Type of Boiler | |

| Boiler Rating | |

| Maximum Continuous Evaporation | |

| Original working Pressure | |

| Hydraulic test Pressure | |

| Inspection during erection | |

| Certificate of boiler, boiler components, mountings, fittings, steam pipes etc in form-II, III, III C IV, IV-A submitted or available for inspection. | Yes/No |

| Boiler Drawings available for inspection. | Yes/No |

| Required fees deposited | Yes/No |

| Approved Steam pipeline drawings available for inspection. | Yes/No

If Yes Approval No. |

|

In case of Boiler to be erected at site and Site welding carried out: (a)Boiler drums, boiler components, mountings, fittings, steam pipes etc. accessible for inspection for any transit damage and verification as per certificates/stamps. |

Yes/No |

| Internal & External Condition of Shell/Drum | Satisfactory/Not Satisfactory |

| Internal & External Condition of Tubes | Satisfactory/Not Satisfactory |

| Internal & External Condition of Headers and boiler components | Satisfactory/Not Satisfactory |

|

(b) Weld joints and test reports should be made available for inspection. Test reports such as Radiography carried out and Reports & films available for inspection. |

Yes/No |

|

Stress relieving reports available for inspection. |

Yes/No |

|

Details of certified welders and recognised boiler repairer. |

|

| Condition of mountings and Fittings | |

| 1.Fusile plug | |

| 2.Feed inlet | |

| 3.Feed check valves and chest | |

| 4.Stop Valves and chest | |

| 5. Water gauge mounting | |

| 6. Safety valves and chest | |

| 7.Blow out apparatus | |

| 8.Steam pressure gauge

i. Makers name and No. ii. Range iii. Red mark at iv. Type |

|

| 9. Mobray / Water level controller | |

| Preparation for hydraulic test | |

|

If the Boiler is in battery, all steam & water & furnace flue communication with another boiler shall be disconnected |

Yes/No |

|

The Safety valves removed and chest opening blank flanged |

Yes/No |

| Boiler completely filled with water | Yes/No |

| Ensure no trap of air | Yes/No |

| The Temperature of water in boiler during Hydraulic Test should be between 20° C and 50° C. | Yes/No |

| Hydraulic test to be taken to 1½ times the maximum Working pressure. | Yes/No |

| Any leakage or deflection noticed. | Yes/No |

| Conclusion- Overall condition of boiler | Satisfactory/Not Satisfactory |

|

Boiler completely filled with water |

Yes/No |

|

Ensure no Air trapped inside boiler. |

Yes/No |

|

Any leakage or deflection noticed. |

Yes/No |

| Boiler Attendant

Certificate no. & Class |

Appointed/Not appointed |

| Boiler Operation Engineer Certificate no. |

Appointed/Not appointed/ Not Required |

| Fuel Used | |

|

Steam use details |

CHECKLIST: INSPECTION FOR RENEWAL OF BOILER CERTIFICATE

| GENERAL INFORMATION | |

|---|---|

| Date of Inspection | |

| Name of Owner/Factory/Premises | |

| Address of Factory/Premises | |

| Registration No. of Boiler | |

| Type of Boiler | |

| Boiler Rating | |

| Maximum Continuous Evaporation | |

| Original working Pressure | |

| Hydraulic test | |

| Required fees deposited | Yes/No |

| Preparation for open inspection | |

|

If the Boiler is in battery, all steam & water & furnace flue communication with another boiler shall be disconnected |

Yes/No |

| Access to/condition and cleaning of Boiler, boiler components, boiler mountings, fittings, steam pipes |

Yes/No Satisfactory/Not satisfactory |

|

Boiler is completely empty |

Yes/No |

|

Boiler is in cold condition |

Yes/No |

|

All essential Parts of boiler such as Safety valve Cleaned properly, scales on tubes inside & outside |

Yes/No |

|

Manhole, Hand Hole, Sight hole are opened to examine boiler from inside. |

Yes/No |

| Internal & External Condition of Shell/Drum | Satisfactory/Not Satisfactory |

| Internal & External Condition of Tubes | Satisfactory/Not Satisfactory |

| Internal & External Condition of Headers and boiler components. | Satisfactory/Not Satisfactory |

| Condition of mountings and Fittings | |

| 1.Fusile plug | |

| 2.Feed inlet | |

| 3.Feed check valves and chest | |

| 4.Stop Valves and chest | |

| 5. Water gauge mounting | |

| 6. Safety valves and chest | |

| 7.Blow out apparatus | |

| 8.Steam pressure gauge

i. Range ii. Red mark at iii. Type |

|

| 9. Mobray / Water level controller | |

| Preparation for hydraulic test | |

|

If the Boiler is in battery, all steam & water & furnace flue communication with another boiler shall be disconnected |

Yes/No |

|

The Safety valves removed and chest opening blank flanged |

Yes/No |

| Boiler completely filled with water | Yes/No |

| Ensure no trap of air | Yes/No |

| Any leakage or deflection noticed. | Yes/No |

| Conclusion- Overall condition of boiler | Satisfactory/Not Satisfactory |

|

Boiler completely filled with water |

Yes/No |

|

Ensure no Air trapped inside boiler. |

Yes/No |

|

water in boiler during Hydraulic Test should be between 20° C and 50° C. |

Yes/No |

|

Hydraulic test to be taken to 1¼ times the maximum Working pressure. |

Yes/No |

|

Any leakage or deflection noticed. |

Yes/No |

|

Repairs carried out/change of mountings (If yes, then details) |

Yes/No |

|

Conclusion- Overall condition of boiler |

Satisfactory/Not Satisfactory |

| Boiler Attendant (Attach list for Name of Boiler Attendant

Certificate no. & Class) |

Appointed/Not appointed |

| Boiler Operation Engineer (Attach list for Name Boiler Operation Engineer &Certificate no.) | Appointed/Not appointed / Not Required |

| Fuel Used | |

| Steam use details |