Inspection procedure of Factories

Inspection procedure and checklist for Factories under the Factories Act, 1948

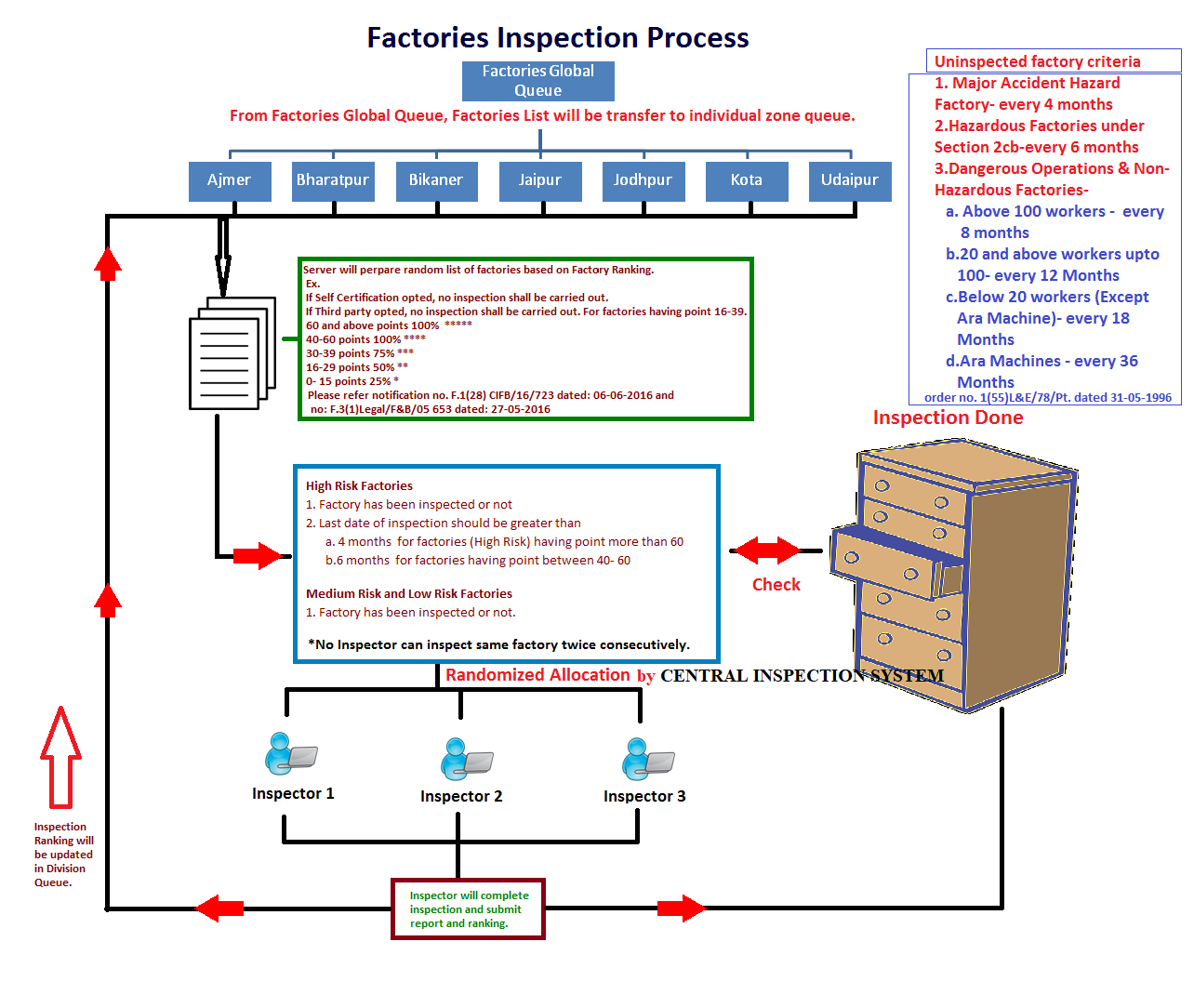

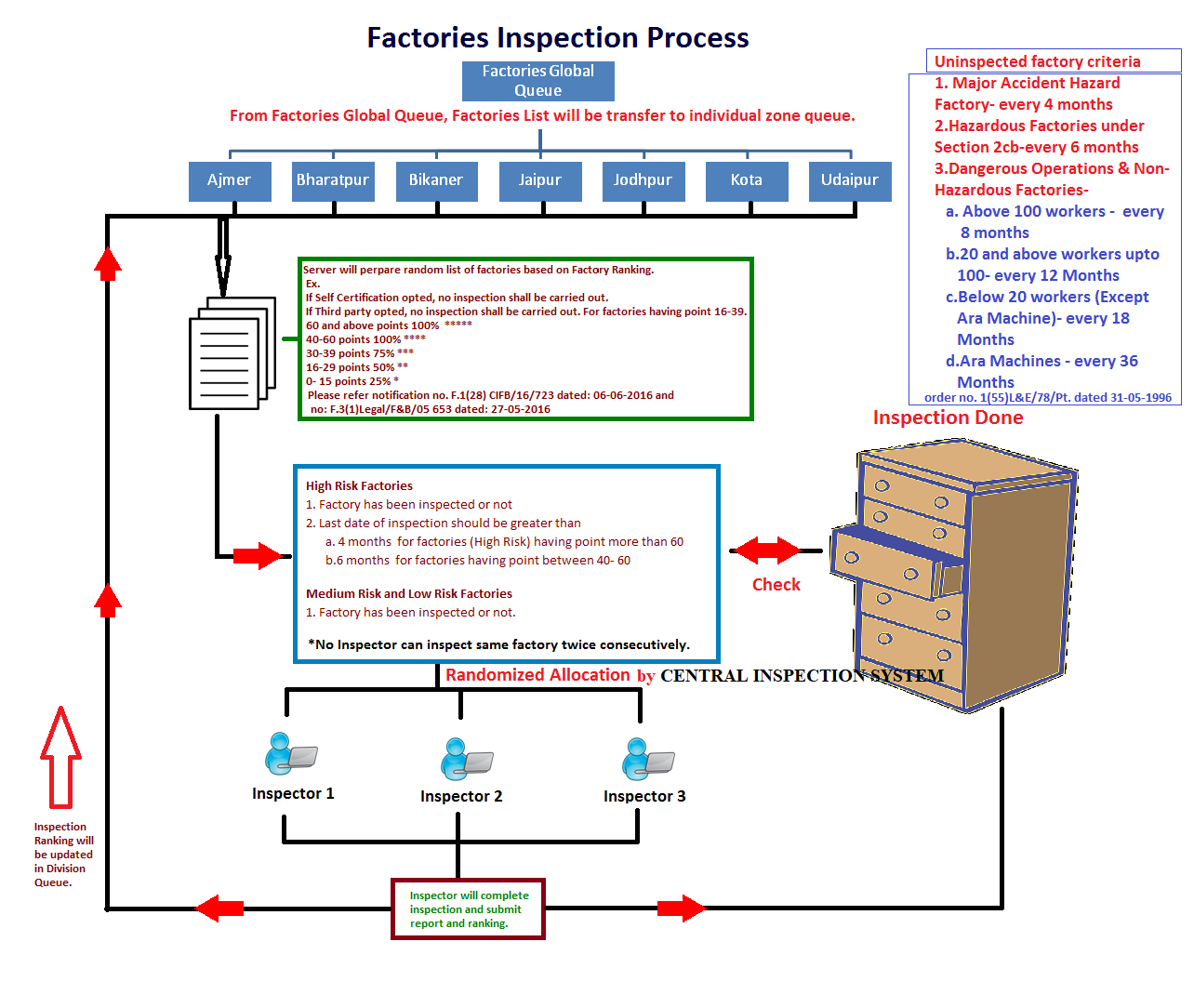

1. Factories are allotted to Inspectors by Central Inspection System (Click here to know more) in randomized manner based on computerized risk assessment based upon risk profile (such as High (Major Accident Hazard), Medium (Hazardous/Dangerous Operation) and Low risk (Non-Hazardous)) of factories targeted to provide streamlined compliance inspection regimes for industries on the basis of their relative risk or hazard levels.

2. Full division is the jurisdiction of each field officer. Inspector can not inspect same factory twice consecutively.

3. Inspector has to carryout synchronized/joint- inspection under The Factories Act, 1948 along with Labour Inspector who is inspecting the same factory under following Labour Laws-

-

Inspection under The Equal Remuneration Act, 1976

-

Inspection under The Maternity Benefit Act, 1961

-

Inspection under The Minimum Wages Act, 1948

-

Inspection under The Shops and Establishments Act (as applicable)

-

Inspection under The Labour Welfare Fund Act (as applicable)

-

Inspection under The Payment of Bonus Act, 1965

-

Inspection under The Payment of Wages Act, 1936

-

Inspection under The Payment of Gratuity Act, 1972

-

Inspection under The Contract Labour (Regulation and Abolition) Act, 1970

4. Surprise inspections are allowed on the basis of complaints received and subject to approval from the Head of Department/District Magistrate.

5. Every inspector shall make a physical visit to factory mentioned in the above list as generated by computer only in point no. 1

6. This inspection report should be shown to be manger or any other responsible person in whose presence the inspection has been carried out and his signature shall be obtained at the end of the inspection note.

7. in case this person concerned refuses to sign on the inspection report prepared on the spot, a note to this affect should be marked at the end of the inspection note.

8. Inspector has to submit inspection report online within 48 hours to the Department and Management of the Factory can also download the inspection report using their account in RajFAB

9. User can see the inspection report and submit compliance, if any, reported by the Inspector.

CHECKLIST FOR THE INSPECTION OF HAZARDOUS FACTORIES.

| S.No. | GENERAL INFORMATION | |

|---|---|---|

|

1 |

Date of Inspection |

|

|

2 |

RJ Number. |

|

|

3 |

Name of Factory |

|

|

4 |

Address of Factory |

|

|

5 |

Total Number of Workers employed Numbers of Male workers Numbers of female workers |

|

|

6 |

Total Power installed in hp/kva/kw |

|

|

7 |

Manufacturing Process |

|

|

8 |

License Renewed up to |

|

|

9 |

Factory building plans Approval detail |

|

|

10 |

Name of Occupier with Mobile No. and Email Address |

|

|

11 |

Name of Factory Manager with Mobile No. and Email Address |

|

|

12 |

Name of responsible person present at the time of inspection |

|

|

13 |

Compliance of last inspection verified |

Yes or No |

SAFETY PROVISIONS:-

| S.No. | Check Points Related to Safety Provisions | Status |

|---|---|---|

|

1 |

Safety guard or fencing are provided to all moving parts of machineries |

Yes or No |

|

2 |

Striking gear and devices are provided for cutting off power in case of any emergency |

Yes or No |

|

3 |

Are there any hoist and lifts used, If yes then examined by competent person |

Yes or No |

|

4 |

Are there any Lifting machines, chains, ropes and lifting tackles available (attach list) |

Available or not Available |

|

5 |

If Lifting machines, chains, ropes and lifting tackles available, examined by competent person |

Yes or No |

|

6 |

Are there any pressure vessels used during process, If yes then examined by competent person (attach list) |

Yes or No |

|

7 |

Floors, stairs and passages are provided and maintained safe means of access to every place at which any person is at any time required to work |

Yes or No |

|

8 |

Any pits, sumps openings in floors are securely covered or fenced |

Yes or No |

|

9 |

Effective measures are provided to control any excess fumes, dust and gas |

Yes / No |

|

10 |

Fire fighting facilities provided to control fire incident in case of fire. |

Yes / No |

|

11 |

Qualified Safety Officers shall be appointed where 1000 workers are ordinarily employed |

Appointed/Not appointed/ Not applicable |

|

12 |

Safety committee shall be constituted in every factory wherein more than 50 workers are ordinarily employed |

Constituted/Not constituted/ Not applicable |

|

13 |

As per Indian standard, Personal Protective equipments like safety belts, helmets, safety shoes ,goggles , mask and gloves are available in sufficient quantity for workers employed therein |

Available/ Not available |

|

14 |

Health and Safety policy prepared in every factory wherein more than 50 workers are ordinarily employed |

Provided /Not provided /Not applicable |

|

15 |

Workers employed in hazardous process are medically examined by factory medical officer or certifying surgeon |

Yes or No |

|

16 |

Health register of workers maintained in form no. 19 |

Yes or No |

|

17 |

Occupational Health Centre shall be provided in every factory wherein more than 500 workers employed |

Provided /Not provided/ Not applicable |

|

18 |

Ambulance van is available |

Yes or No |

|

19 |

Sensors with alarm system are provided for detection of leakage of chemicals |

Yes / No/Not applicable |

|

20 |

In case of leakage of chemicals, Proper Neutralization Arrangements provided |

Provided/ not provided/Not applicable |

|

21 |

Safety Precautions Board displayed at various approach location within factory premises |

Yes or No |

|

22 |

Safety training given to all workers |

Yes or No |

|

23 |

Record of Safety training given to all workers maintained |

Yes or No |

|

24 |

Safety relating to Manufacturing Process |

Complied with/Not complied with |

HEALTH PROVISIONS:-

| S.No. | Check Points Related to Health Provisions | Status |

|---|---|---|

|

1 |

Cleanliness status of work place such as Floors, stairs and passages are cleanliness |

Yes or No |

|

2 |

Effective arrangements are provided for the treatment of waste and effluents |

Yes or No |

|

3 |

Effective arrangements are provided for control of excess dust and fumes |

Yes or No |

|

4 |

Drinking water facilities available in factory |

Yes or No |

|

5 |

Latrines and urinals are provided in proportion to the no. of male and female workers employed |

Yes or No |

|

6 |

Latrines and urinals are connected to sewerage system |

Yes or No |

|

7 |

Sufficient and suitable lighting (natural or artificial or both) shall be provided in every part of factories |

Yes or No |

WELFARE PROVISIONS:-

|

1 |

Adequate and suitable facilities for washing provided and maintained for the use of the workers |

Yes or No |

|

2 |

First aid facilities available in factory |

Yes or No |

|

3 |

Canteen provided in every factory wherein more than 250 workers are ordinarily employed |

Yes / No/Not applicable |

|

4 |

Shelters, rest rooms and lunch rooms provided in every factory wherein more than 150 workers are ordinarily employed |

Yes / No/Not applicable |

|

5 |

Creches provided in every factory wherein more than 30 women workers are ordinarily employed |

Yes / No/Not applicable |

|

6 |

Welfare officer shall be appointed in every factory wherein more than 500 workers employed |

Appointed/Not appointed/Not applicable |

|

7 |

Ambulance room provided in every factory wherein more than 500 workers are ordinarily employed |

Provided /Not provided/Not applicable |

RECORD KEEPING PROVISIONS:-

|

1 |

Following Records are to be produced:-

|

Yes or No Yes or No Yes or No Yes or No Yes or No Yes or No |

|

2 |

Single Integrated Return submitted |

Yes or No |

|

3 |

Building Stability Certificate received from competent person |

Yes or No |

CHECKLIST FOR THE INSPECTION OF FACTORIES CARRIED OUT DANGEROUS OPERATION

|

GENERAL INFORMATION |

||

|

1 |

Date of Inspection |

|

|

2 |

RJ Number. |

|

|

3 |

Name of Factory |

|

|

4 |

Address of Factory |

|

|

5 |

Total Number of Workers employed Numbers of Male workers Numbers of female workers |

|

|

6 |

Total Power installed in hp/kva/kw |

|

|

7 |

Manufacturing Process |

|

|

8 |

License Renewed up to |

|

|

9 |

Factory building plans Approval detail |

|

|

10 |

Name of Occupier with Mobile No. and Email Address |

|

|

11 |

Name of Factory Manager with Mobile No. and Email Address |

|

|

12 |

Name of responsible person present at the time of inspection |

|

|

13 |

Compliance of last inspection verified |

Yes or No |

SAFETY PROVISIONS:-

|

1 |

Safety guard or fencing are provided to all moving parts of machineries |

Yes or No |

|

2 |

Striking gear and devices are provided for cutting off power in case of any emergency |

Yes or No |

|

3 |

Are there any hoist and lifts used, If yes then examined by competent person |

Yes or No |

|

4 |

Are there any Lifting machines, chains, ropes and lifting tackles available (Attach List) |

Available or not Available |

|

5 |

If Lifting machines, chains, ropes and lifting tackles available, examined by competent person |

Yes or No |

|

6 |

Are there any pressure vessels used during process, If yes then examined by competent person (Attach List) |

Yes or No |

|

7 |

Floors, stairs and passages are provided and maintained safe means of access to every place at which any person is at any time required to work |

Yes or No |

|

8 |

Any pits, sumps openings in floors are securely covered or fenced |

Yes or No |

|

9 |

Effective measures are provided to control any excess fumes, dust and gas |

Yes / No |

|

10 |

Fire fighting facilities provided to control fire incident in case of fire |

Yes / No |

|

11 |

Qualified Safety Officers shall be appointed where 1000 workers are ordinarily employed |

Appointed/Not appointed/ Not applicable |

|

12 |

Safety committee shall be constituted in every factory wherein more than 50 workers are ordinarily employed |

Constituted/Not constituted/ Not applicable |

|

13 |

As per Indian standard, Personal Protective equipments like safety belts, helmets, safety shoes ,goggles , mask and gloves are available in sufficient quantity for workers employed therein |

Available/ Not available |

|

14 |

Health and Safety policy prepared in every factory wherein more than 50 workers are ordinarily employed |

Provided /Not provided /Not applicable |

|

15 |

Workers employed in hazardous process are medically examined by factory medical officer or certifying surgeon |

Yes or No |

|

16 |

Health register of workers maintained in form no. 19 |

Yes or No |

|

17 |

Occupational Health Centre shall be provided in every factory wherein more than 500 workers employed |

Provided /Not provided/ Not applicable |

|

18 |

Sensors with alarm system are provided for detection of leakage of chemicals |

Yes / No/Not applicable |

|

19 |

In case of leakage of chemicals, Proper Neutralization Arrangements provided |

Provided/ not provided/Not applicable |

|

20 |

Safety Precautions Board displayed at various approach location within factory premises |

Yes or No |

|

21 |

Safety training given to all workers |

Yes or No |

|

22 |

Record of Safety training given to all workers maintained |

Yes or No |

HEALTH PROVISIONS:-

|

1 |

Cleanliness status of work place such as Floors, stairs and passages |

Good/Satisfactory/Need Improvement |

|

2 |

Effective arrangements are provided for the treatment of waste and effluents |

Yes or No |

|

3 |

Effective arrangements are provided for control of excess dust and fumes |

Yes or No |

|

4 |

Drinking water facilities available in factory |

Yes or No |

|

5 |

Latrines and urinals are provided in proportion to the no. of male and female workers employed |

Yes or No |

|

6 |

Latrines and urinals are connected to sewerage system |

Yes or No |

|

7 |

Sufficient and suitable lighting (natural or artificial or both) shall be provided in every part of factories |

Yes or No |

WELFARE PROVISIONS:-

| S.No. | Check Points Related to Welfare Provisions | Status |

|

1 |

Adequate and suitable facilities for washing provided and maintained for the use of the workers |

Yes or No |

|

2 |

First aid Facilities available in factory |

Yes or No |

|

3 |

Canteen provided in every factory wherein more than 250 workers are ordinarily employed |

Yes / No/ Not Applicable |

|

4 |

Shelters, rest rooms and lunch rooms provided in every factory wherein more than 150 workers are ordinarily employed |

Yes / No/ Not Applicable |

|

5 |

Creches provided in every factory wherein more than 30 women workers are ordinarily employed |

Yes / No/ Not Applicable |

|

6 |

Welfare officer shall be appointed in every factory wherein more than 500 workers employed |

Appointed/Not appointed/ Not Applicable |

|

7 |

Ambulance room provided in every factory wherein more than 500 workers are ordinarily employed |

Provided /Not provided/ Not Applicable |

OTHER PROVISIONS:-

|

S.No. |

Check Points Related to Other Provisions |

Status |

|---|---|---|

|

1 |

Following Records are to be produced:-

|

Yes or No Yes or No Yes or No Yes or No Yes or No Yes or No |

|

2 |

Single Integrated Return submitted |

Yes or No |

|

4 |

Building Stability Certificate received from competent person |

Yes or No |

CHECKLIST FOR THE INSPECTION OF NON HAZARDOUS FACTORIES

|

GENERAL INFORMATION |

||

|

1 |

Date of Inspection |

|

|

2 |

RJ Number. |

|

|

3 |

Name of Factory |

|

|

4 |

Address of Factory |

|

|

5 |

Total Number of Workers employed Numbers of Male workers Numbers of female workers |

|

|

6 |

Total Power installed in hp/kva/kw |

|

|

7 |

Manufacturing Process |

|

|

8 |

License Renewed up to |

|

|

9 |

Factory building plans Approval detail |

|

|

10 |

Name of Occupier with Mobile No. and Email Address |

|

|

11 |

Name of Factory Manager with Mobile No. and Email Address |

|

|

12 |

Name of responsible person present at the time of inspection |

|

|

13 |

Compliance of last inspection verified |

Yes or No |

SAFETY PROVISIONS:-

|

1 |

Safety guard or fencing are provided to all moving parts of machineries |

Yes or No |

|

2 |

Striking gear and devices are provided for cutting off power in case of any emergency |

Yes or No |

|

3 |

Are there any hoist and lifts used, If yes then examined by competent person |

Yes or No |

|

4 |

Are there any Lifting machines, chains, ropes and lifting tackles available (Attach List) |

Available or not Available |

|

5 |

If Lifting machines, chains, ropes and lifting tackles available, examined by competent person |

Yes or No |

|

6 |

Are there any pressure vessels used during process, If yes then examined by competent person (Attach List) |

Yes or No |

|

7 |

Floors, stairs and passages are provided and maintained safe means of access to every place at which any person is at any time required to work |

Yes or No |

|

8 |

Any pits, sumps openings in floors are securely covered or fenced |

Yes or No |

|

9 |

Effective measures are provided to control any excess fumes, dust and gas |

Yes / No |

|

10 |

Fire fighting facilities provided to control fire incident in case of fire |

Yes / No |

|

11 |

Qualified Safety Officers shall be appointed where 1000 workers are ordinarily employed |

Appointed/Not appointed/ Not applicable |

|

12 |

As per Indian standard, Personal Protective equipments like safety belts, helmets, safety shoes ,goggles , mask and gloves are available in sufficient quantity for workers employed therein |

Available/ Not available |

|

13 |

Health and Safety policy prepared in every factory wherein more than 100 workers are ordinarily employed |

Provided /Not provided /Not applicable |

|

14 |

Safety Precautions Board displayed at various approach location within factory premises |

Yes or No |

|

15 |

Safety training given to all workers |

Yes or No |

|

16 |

Record of Safety training given to all workers maintained |

Yes or No |

HEALTH PROVISIONS:-

|

S.No. |

Check Points Related to Health Provisions |

Status |

|

1 |

Cleanliness status of work place such as Floors, stairs and passages |

Good/Satisfactory/Need Improvement |

|

2 |

Effective arrangements are provided for the treatment of waste and effluents |

Yes or No |

|

3 |

Effective arrangements are provided for control of excess dust and fumes |

Yes or No |

|

4 |

Drinking water facilities available in factory |

Yes or No |

|

5 |

Latrines and urinals are provided in proportion to the no. of male and female workers employed |

Yes or No |

|

6 |

Latrines and urinals are connected to sewerage system |

Yes or No |

|

7 |

Sufficient and suitable lighting (natural or artificial or both) shall be provided in every part of factories |

Yes or No |

WELFARE PROVISIONS:-

|

S.No. |

Check Points Related to Welfare Provisions |

Status |

|

1 |

Adequate and suitable facilities for washing provided and maintained for the use of the workers |

Yes or No |

|

2 |

First aid Facilities available in factory |

Yes or No |

|

3 |

Canteen provided in every factory wherein more than 250 workers are ordinarily employed |

Yes / No/ Not Applicable |

|

4 |

Shelters, rest rooms and lunch rooms provided in every factory wherein more than 150 workers are ordinarily employed |

Yes / No/ Not Applicable |

|

5 |

Crèches provided in every factory wherein more than 30 women workers are ordinarily employed |

Yes / No/ Not Applicable |

|

6 |

Welfare officer shall be appointed in every factory wherein more than 500 workers employed |

Appointed/Not appointed/ Not Applicable |

|

7 |

Ambulance room provided in every factory wherein more than 500 workers are ordinarily employed |

Provided /Not provided/ Not Applicable |

RECORD KEEPING PROVISIONS:-

|

1 |

Following Records are to be produced:-

|

Yes or No Yes or No Yes or No Yes or No Yes or No Yes or No |

|

2 |

Single Integrated Return submitted |

Yes or No |

|

3 |

Building Stability Certificate received from competent person |

Yes or No |

CHECKLIST FOR THE INSPECTION OF NON POWER AND NON HAZARDOUS FACTORIES

|

GENERAL INFORMATION |

||

|

1 |

Date of Inspection |

|

|

2 |

RJ Number. |

|

|

3 |

Name of Factory |

|

|

4 |

Address of Factory |

|

|

5 |

Total Number of Workers employed Numbers of Male workers Numbers of female workers |

|

|

6 |

Manufacturing Process |

|

|

7 |

License Renewed up to |

|

|

8 |

Factory building plans Approval detail |

|

|

9 |

Name of Occupier with Mobile No. and Email Address |

|

|

10 |

Name of Factory Manager with Mobile No. and Email Address |

|

|

11 |

Name of responsible person present at the time of inspection |

|

|

12 |

Compliance of last inspection verified |

Yes or No |

SAFETY PROVISIONS:-

|

S.No. |

Check Points Related to Safety Provisions |

Status |

|

1 |

Floors, stairs and passages are provided and maintained safe means of access to every place at which any person is at any time required to work |

Yes or No |

|

2 |

Any pits, sumps openings in floors are securely covered or fenced |

Yes or No |

|

3 |

Fire fighting facilities provided to control fire incident in case of fire, Detail of plan available |

Yes / No |

|

4 |

As per Indian standard, Personal Protective equipments like safety belts, helmets, safety shoes ,goggles , mask and gloves are available in sufficient quantity for workers employed therein |

Available/ Not available |

|

5 |

Health and Safety policy prepared in every factory wherein more than 100 workers are ordinarily employed |

Provided /Not provided /Not applicable |

|

6 |

Safety Precautions Board displayed at various approach location within factory premises |

Yes or No |

|

7 |

Safety training given to all workers |

Yes or No |

|

8 |

Record of Safety training given to all workers maintained |

Yes or No |

|

9 |

Safety relating to Manufacturing Process |

Complied with/Not complied with |

|

10 |

Compliance of last inspection verified |

Yes or No |

HEALTH PROVISIONS:-

| S.No. | Check Points Related to Health Provisions | Status |

|---|---|---|

|

1 |

Cleanliness status of work place such as Floors, stairs and passages |

Good/Satisfactory/Need Improvement |

|

2 |

Effective arrangements are provided for the treatment of waste and effluents |

Yes or No |

|

3 |

Effective arrangements are provided for control of excess dust and fumes |

Yes or No |

|

4 |

Drinking water facilities available in factory |

Yes or No |

|

5 |

Latrines and urinals are provided in proportion to the no. of male and female workers employed |

Yes or No |

|

6 |

Latrines and urinals are connected to sewerage system |

Yes or No |

|

7 |

Sufficient and suitable lighting (natural or artificial or both) shall be provided in every part of factories |

Yes or No |

|

8 |

Sufficient no. of Spittoons are provided |

Yes or No |

WELFARE PROVISIONS:-

|

S.No. |

Check Points Related to Welfare Provisions |

Status |

|

1 |

Adequate and suitable facilities for washing provided and maintained for the use of the workers |

Yes or No |

|

2 |

First aid Facilities available in factory |

Yes or No |

|

3 |

Crèches provided in every factory wherein more than 30 women workers are ordinarily employed |

Yes / No/ Not Applicable |

RECORD KEEPING PROVISIONS:-

| S.No. | Check Points Related to Other Provisions | Status |

|---|---|---|

|

1 |

Following Records are to be produced:-

|

Yes or No Yes or No Yes or No Yes or No Yes or No Yes or No |

|

2 |

Single Integrated Return submitted |

Yes or No |

|

3 |

Building Stability Certificate received from competent person |

Yes or No |

CHECKLIST FOR THE INSPECTION OF MAJOR ACCIDENT HAZARD (MAH) FACTORIES.

| GENERAL INFORMATION | ||

|---|---|---|

|

1 |

Date of Inspection |

|

|

2 |

RJ Number. |

|

|

3 |

Name of Factory |

|

|

4 |

Address of Factory |

|

|

5 |

Total Number of Workers employed Numbers of Male workers Numbers of female workers |

|

|

6 |

Total Power installed in hp/kva/kw |

|

|

7 |

Manufacturing Process |

|

|

8 |

License Renewed up to |

|

|

9 |

Factory building plans Approval detail |

|

|

10 |

Name of Occupier with Mobile No. and Email Address |

|

|

11 |

Name of Factory Manager with Mobile No. and Email Address |

|

|

12 |

Name of responsible person present at the time of inspection |

|

|

13 |

Compliance of last inspection verified |

Yes or No |

SAFETY PROVISIONS:-

| S.No. | Check Points Related to Safety Provisions | Status |

|---|---|---|

|

1 |

Safety guard or fencing are provided to all moving parts of machineries |

Yes or No |

|

2 |

Striking gear and devices are provided for cutting off power in case of any emergency |

Yes or No |

|

3 |

Are there any hoist and lifts used, If yes then examined by competent person |

Yes or No |

|

4 |

Are there any Lifting machines, chains, ropes and lifting tackles available (Attach List) |

Available or not Available |

|

5 |

If Lifting machines, chains, ropes and lifting tackles available, examined by competent person |

Yes or No |

|

6 |

Are there any pressure vessels used during process, If yes then examined by competent person (Attach List) |

Yes or No |

|

7 |

Floors, stairs and passages are provided and maintained safe means of access to every place at which any person is at any time required to work |

Yes or No |

|

8 |

Any pits, sumps openings in floors are securely covered or fenced |

Yes or No |

|

9 |

Effective measures are provided to control any excess fumes, dust and gas |

Yes / No |

|

10 |

Whether the following systems are provided to chemical storage vessels/tanks

|

|

|

11 |

Fire fighting facilities provided to control fire incident in case of fire |

Yes / No |

|

12 |

Qualified Safety Officers shall be appointed where 1000 workers are ordinarily employed |

Appointed/Not appointed/ Not applicable |

|

13 |

Safety committee shall be constituted in every factory wherein more than 50 workers are ordinarily employed |

Constituted/Not constituted/ Not applicable |

|

14 |

As per Indian standard, Personal Protective equipments like safety belts, helmets, safety shoes ,goggles , mask and gloves are available in sufficient quantity for workers employed therein |

Available/ Not available |

|

15 |

Health and Safety policy prepared in every factory wherein more than 50 workers are ordinarily employed |

Provided /Not provided /Not applicable |

|

16 |

Workers employed in hazardous process are medically examined by factory medical officer or certifying surgeon |

Yes or No |

|

17 |

Health register of workers maintained in form no. 19 |

Yes or No |

|

18 |

Occupational Health Centre shall be provided in every factory wherein more than 500 workers employed |

Provided /Not provided/ Not applicable |

|

19 |

Ambulance van is available |

Yes or No |

|

20 |

Sensors with alarm system are provided for detection of leakage of chemicals |

Yes / No |

|

21 |

In case of leakage of chemicals, Proper Neutralization Arrangements provided |

Provided/ not provided |

|

22 |

Safety Precautions Board displayed at various approach location within factory premises |

Yes or No |

|

23 |

Whether mutual aid agreement with other organization is available |

Yes or No |

|

24 |

Has the management prepared on-site emergency plan |

Yes or No |

|

25 |

On-site emergency plan last updated on |

|

|

26 |

Date of last two mock drills conducted as per On-site emergency plan |

|

|

27 |

Public liability insurance policy available |

Yes or No |

|

28 |

Technique adopted to assess the hazards

|

|

|

29 |

Whether safety audit report required as per RCIMAH rules 1991 |

Yes / No/Not applicable |

|

30 |

If safety audit report required then carried out by approved by third party as per RCIMAH rules 1991 |

Yes or No |

|

31 |

Status of compliance of recommendations given in safety audit report |

Complied/not complied |

|

32 |

Awareness Program regarding hazards conducted to nearby vicinity of factory premises |

Yes or No |

|

33 |

Safety training given to all workers |

Yes or No |

|

34 |

Record of Safety training given to all workers maintained |

Yes or No |

|

24 |

Safety relating to Manufacturing Process |

Complied with/Not complied with |

HEALTH PROVISIONS:-

| S.No. | Check Points Related to Health Provisions | Status |

|---|---|---|

|

1 |

Cleanliness status of work place such as Floors, stairs and passages |

Good/Satisfactory/Need Improvement |

|

2 |

Effective arrangements are provided for the treatment of waste and effluents |

Yes or No |

|

3 |

Effective arrangements are provided for control of excess dust and fumes |

Yes or No |

|

4 |

Drinking water facilities available in factory |

Yes or No |

|

5 |

Latrines and urinals are provided in proportion to the no. of male and female workers employed |

Yes or No |

|

6 |

Latrines and urinals are connected to sewerage system |

Yes or No |

|

7 |

Sufficient and suitable lighting (natural or artificial or both) shall be provided in every part of factories |

Yes or No |

|

8 |

Health safety relating to Manufacturing Process |

Complied with/Not complied with |

WELFARE PROVISIONS:-

|

S.No. |

Check Points Related to Welfare Provisions | Status |

|---|---|---|

|

1 |

Adequate and suitable facilities for washing provided and maintained for the use of the workers |

Yes or No |

|

2 |

First aid Facilities available in factory |

Yes or No |

|

3 |

Canteen provided in every factory wherein more than 250 workers are ordinarily employed |

Yes / No/ Not Applicable |

|

4 |

Shelters, rest rooms and lunch rooms provided in every factory wherein more than 150 workers are ordinarily employed |

Yes / No/ Not Applicable |

|

5 |

Creches provided in every factory wherein more than 30 women workers are ordinarily employed |

Yes / No/ Not Applicable |

|

6 |

Welfare officer shall be appointed in every factory wherein more than 500 workers employed |

Appointed/Not appointed/ Not Applicable |

|

7 |

Ambulance room provided in every factory wherein more than 500 workers are ordinarily employed |

Provided /Not provided/ Not Applicable |

RECORD KEEPING PROVISIONS:-

| S.No. | Check Points Related to Other Provisions | Status |

|---|---|---|

|

1 |

Following Records are to be produced:-

|

Yes or No Yes or No Yes or No Yes or No Yes or No Yes or No |

|

2 |

Single Integrated Return submitted |

Yes or No |

|

4 |

Building Stability Certificate received from competent person |

Yes or No |